IN-PLANT TRAINING

Prestrade Company brings customized training solutions to your plant with content tailored to your unique needs.

-

Train multiple employees consistently and cost effectively in your facility

-

Meet your company’s specific training requirements by customizing content from one or more programs

-

Address your company’s most critical needs through interactive class discussions and team problem solving

-

All in-plant training is customized to meet the specific needs of your company, including: Press types, die types, feed-line configuration, material types and grades used, operator skill level (new, incumbent), etc.

PRESS MAINTENANCE + SAFETY TRAINING

Press Maintenance, Troubleshooting and Safety Training seminars are customized to each specific company or facility.

CLICK TO VIEW a sample agenda for a 2-Day, In-Plant training session.

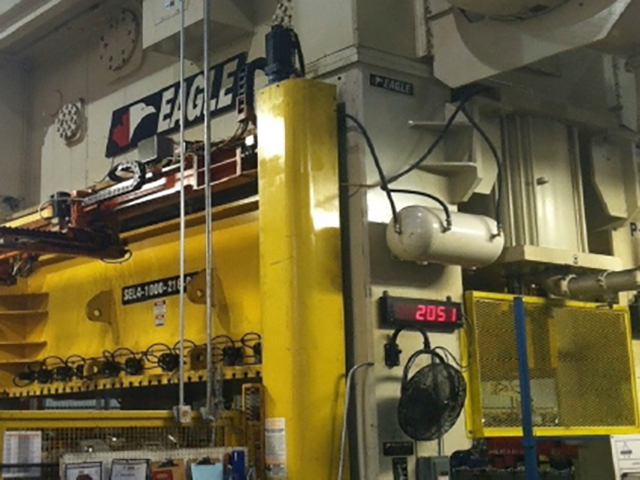

ENGINEERING

Jeff Fredline has over 40 years experience in the Metal Stamping Press Industry, with extensive experience in metal stamping on both the machinery and production sides. Jeff’s expertise and services include:

-

Metal stamping press technical services

-

New/used machinery sales

-

Presses, feed systems and tool room equipment

-

Machinery upgrades and rebuilding

-

Clutches, brakes and clutch-brake conversions

-

Authorized representative of Torque Technologies, Inc., the exclusive US distributor for GOIZPER clutches, brakes and clutch-brakes and GUIBE gearboxes.

-

INSTALLATION

Jeff’s extensive experience in the Metal Stamping Press Industry, selling and servicing machinery and production capacities, enables him to provide detailed project management and, if needed, complete turnkey services for:

-

Machine installation and commissioning

-

Feed line installation

-

Overall project management and budget forecasting

-

Decommission of machinery

MAKE PROACTIVE MAINTENANCE AND PRESS SAFETY A PRIORITY IN YOUR FACILITY.

Prestrade Company

6283 Cotton Tail Lane

Morristown, TN 37814

Contact: Jeff Fredline, President

Call: 615-517-4282

Email: jeff@prestradesolutions.com